A mineral analysis workflow for drill cuttings at the wellsite: applications to geothermal and petroleum resource exploration, appraisal and development

P Joseph Hamilton*, Carmen Harris and Sigrid Hillier.

Ana-min, Perth, Western Australia

Extended Abstract

6th Geological Conference of The Geological Society of Trinidad and Tobago

Knowledge of the mineralogy of drill cuttings can translate to high value information for all phases of energy resource exploration and exploitation. Mineralogy can variously provide correlations between wells, mineral markers for geo-steering application and setting casing points, constraints for mineral models for log interpretation, subsurface temperature distributions for geothermal resource assessment and explanations of formation damage (Hamilton and Ly, 2012). In addition, scale minerals, that may form in wells and surface facilities and cause costly reductions in productivity and injectivity (Gunnarsson and Arnórsson, 2005) may be rapidly identified. This enables remedial and preventative strategies to be employed in a timely manner.

Where cores and/or legacy cuttings are available, stage one of the workflow comprises comprehensive mineralogical analysis of the available samples. Analytical methods employed include X Ray Diffraction (XRD, Poppe et al., 2001), thin section petrography (Raith et al., 2011), scanning electron microscopy /energy dispersive X ray spectrometry (SEM/EDS, Ayling et al., 2012)) and bench top Fourier Transform Infrared spectrometry (FTIR, Adamu, 2010; Hamilton et al., 2014). The workflow stage 2 is undertaken at the wellsite. It comprises use of benchtop FTIR analyses of ~ 5gm of representative samples of bulk washed and dried cuttings. Samples are reduced to fine powder by grinding with an agate mortar and pestle prior to analysis. This technique is attractive for wellsite deployment as sample preparation and analysis are simple and rapid, and the equipment occupies only a small footprint.

Spectrometry is the measurement of responses in which a mineral absorbs, reflects, changes, or emits electromagnetic waves. IR spectrometry is the measurement of wavelength and intensity of absorption of mid-infrared light by a sample. Bonds between atoms and groups of atoms vibrate in different ways and at different frequencies. When the frequency of the IR is the same as the vibrational frequency of a bond, absorption occurs. The specific wavelengths absorbed allow identification of the atomic bonds and their host molecules. The mid-range of 2.5 to 25 mm, or 4000 to 400 cm-1 (wave number), includes ‘fingerprint peaks’ of many minerals. Fourier transform refers to the mathematical deconvolution of the signal into its component peaks. An IR spectrum (Figure 1) is plotted as absorbance units against wave number, where absorbance is the natural log of the incident radiation power to the transmitted power.

Figure 1. Absorption spectrum for a mineral mixture.

Figure 1 shows the IR spectrum of a mineral mixture of dolomite, quartz and illite. Not only can these minerals be identified but they can be quantified by application of Beer’s Law.

This states that the total absorbance (A) is a function of the absorptivity ( ) and concentration (c) of each component and the path length of the IR beam in the sample.

The FTIR technique uses the intensity and amounts of absorption of mid infrared frequencies for identification of many minerals of interest. For petroleum well application the FTIR analysis provides normalised mineral abundances for quartz, feldspars, three carbonates (calcite, dolomite, siderite) and four clays (illite, montmorillonite, chlorite, kaolinite) - the ten most common minerals in sedimentary rocks.

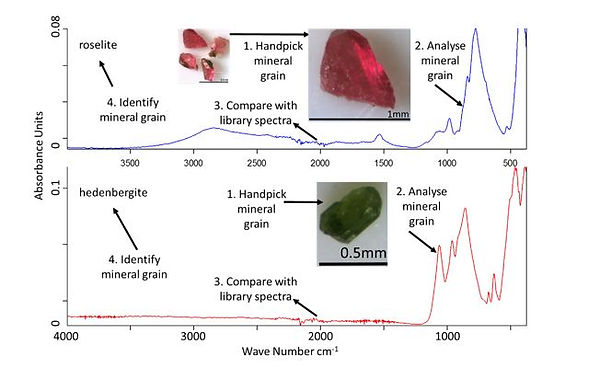

The workflow stage 3 is applied at the wellsite or, after drilling, in the laboratory. It comprises the handpicking and analysis of ~20 to 50 mg of particles of individual lithotypes. For geothermal wells, it is the identification, rather than the quantification, of key minerals indicative of the conditions of hydrothermal alteration that is important. Such minerals (e.g. epidote, actinolite, xonotlite, hydrogrossular, wairakite) include many that are not in the mineral library used for abundance quantification for petroleum related samples. Expert visual inspection of spectra may be used in the laboratory for identification of many of these key hydrothermal minerals. This is not a desirable aspect for a proposed geothermal wellsite application. Consequently, we have developed a stage 4 of the wellsite workflow whereby individual minerals are sampled by handpicking and / or with a scalpel, in amounts as small as a milligram. The resultant spectrum is then automatically compared to a spectral library for more than 350 minerals resulting in correct identification of all minerals of interest (Figure 2).

Figure 2. Illustration of workflow stage 4 for single mineral grain identification.

The pink mineral grain shown in Figure 2 was automatically identified as roselite, a hydrous cobalt arsenate, Ca₂(Co,Mg)[AsO₄]₂·H₂O, and generally associated with hydrothermal mineralization. The green mineral grain shown in Figure 2 was automatically identified as hedenbergite, a pyroxene that occurs in a variety of igneous and metamorphic rocks.

This workflow has been developed over the past few years through onshore and offshore petroleum wellsite projects in Australian and SE Asian basins and laboratory based projects. Petroleum projects have comprised both conventional carbonate and siliciclastic petroleum systems as well as unconventional shale plays. Geothermal projects have been laboratory based and focused on defining downhole temperatures zones that can be used for establishing subsurface temperature distributions that can be variously used for recognising recharge and discharge zones and the size of the geothermal energy resource.

References

Adamu, M.B., 2010, Fourier Transform Infrared Spectroscopic Determination of Shale Minerals in Reservoir Rocks. Nigerian J. Basic Appl. Sci., 18, 6-18.

Ayling, B., Rose, P., Petty, S, Zemach, E. and Drakos, P., 2012. QEMSCAN: Capability and application to fracture characterization in geothermal systems. Proc., Thirty-Seventh Workshop on Geothermal Reservoir Engineering Stanford University, California.

Gunnarsson, I., and Arnórsson, S., 2005: Impact of silica scaling efficiency of heat extraction from high temperature geothermal fluids. Geothermics, 34, 320-329.

Hamilton, P.J. and Ly, C.V., 2012. The Relevance of Mineralogy to The Life Cycle of a Petroleum field. Proc. 5th Geological Conf. and Exhibition, Geol. Soc. Trinidad and Tobago.

Hamilton, P.J., Harris, C. and Hillier, S., 2016. Characterisation of Geothermal Systems Through FTIR Mineral Analysis of Drill Cuttings for Exploration, Appraisal and Development. Proc. 4th Indonesia Intl. Geothermal Conv. & Exhibition. 10 - 12 August, Jakarta, Indonesia.

Poppe, L.J., Paskevich V.F., Hathaway J.C. and Blackwood D.S., 2001. A Laboratory Manual for X-Ray Powder Diffraction. U. S. Geological Survey Open-File Report 01-041.

Raith, M.M. Raase, P. and Reinhardt, J., 2012. Guide to thin section microscopy. Second Edition. ISBN 978-3-00-037671-9 (PDF)